Hydraulic Cylinder Terminology

Back Pressure - Back pressure is the pressure that the cylinder sees trying to get the oil out of the cylinder. The back pressure may be caused by internal restriction within the cylinder or something going on within the hydraulic circuit such as a flow control valve. When back pressure exists, it can create heat as well as take away from the cylinder’s net force it can produce.

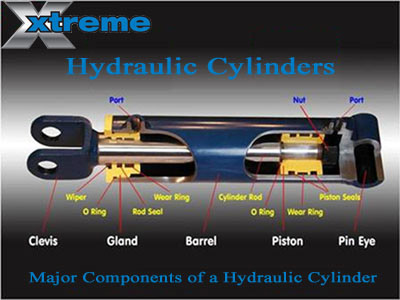

Barrel - The barrel is the cylindrical body of the cylinder. The barrel guides the piston and provides a sealing surface for the piston seal. The barrel is also the structural part of the cylinder that the holds the ends in place.

Boot - or Rod Boot This is a bellows type devise that is put over the rod of a cylinder to help protect the rod and or rod seals. The boots are made from a variety of different materials that are best suited for the application conditions. In some instances boots are used in steel mills to help protect from the heat. In other instances boots are used to protect the cylinder from corrosive chemicals or severely dirty conditions.

Burst Pressure - urst pressure is the pressure in PSI (pounds per square inch) when the pressure vessel or cylinder reaches a point where it is destroyed or ripped apart.

Bypass or Poppet Valve - This is a valve that is installed in the piston of a cylinder. This valve allows the oil flow and pressure in a cylinder go from one side of the piston to the other when the cylinder reaches its end of travel.

Column Strength - Column strength is the maximum load in pounds that a cylinder is able to withstand before it buckles causing a catastrophic failure.

Counterbalance Valve - A counterbalance valve is a load holding valve that is used on hydraulic cylinders. The counterbalance valve uses internal pilot pressure to open the valve in order to allow the cylinder to move. A counterbalance valve is variable in how much it opens which provides a better chance for smooth operation as compared to a check valve.

Cushion - A Cushion is an option on a cylinder that slows it down before the travel reaches the end of stroke. The cushion can be on the extend side of the cylinder or on the retract side or both. The cushion is utilized in a cylinder to keep it and the load from banging for the reduction in noise and or increase life of the apparatus it is moving. The rate of the cushions can either be fixed or adjustable depending upon the design.

Displacement Hydraulic Cylinder - A displacement cylinder is a single acting cylinder that is only power extend as it works on the area of the rod.

Double Acting Hydraulic Cylinder - A double acting cylinder is a cylinder that has power in both the extend and retract directions.

Flow Control Valve - A flow control valve is a valve that restricts the flow of hydraulic oil. This valve can be used to control the speed of a cylinder.

Flow Fuse - A flow fuse is a special valve that shuts off oil flow if the volume of oil exceeds the predetermined limits set. This is used as a safety mechanism within a hydraulic cylinder that will stop it from moving if it travels too fast which could be the result of a hydraulic hose breaking.

Head Gland (Stuffing Box) - The head gland or stuffing box is a cylinder component that serves more than one purpose. It retains the static and dynamic seals at the head end the cylinder, it seals off the oil at the end of the cylinder, it is the support or guide for the rod and it is the mechanical stop to keep the piston from falling out of the cylinder barrel.

Induced Pressure - Induced pressure is the pressure in the cylinder as a result of external load and factors and not as a result of the system pressure. In many cases, induced pressure can be significantly higher than that of system operating pressure. Induced pressure can cause serious damage to a cylinder when not anticipated and should be considered as part of the sizing process when looking at a new cylinder application.

Limit Switch - Limit switch is a very generic term for referencing an electrical switch that is energized when something comes in contact with it. When referenced synonymous with cylinders, it is in the context of an end of stroke switch. That is to say that the switch is mounted to the cylinder in a manner that provides an electric signal when the cylinder is at the end of it its travel for special hydraulic system requirements.

Linear Transducer - Linear transducer is a device that transforms linear position of the cylinder to an electrical signal. This electrical signal is sent to a micro processor for control of the cylinder. Also see Smart Cylinder

Load Holding Valve - Load Hold Valve is a valve that can be mounted externally on the cylinder or incorporated into an end cap to prevent the cylinder from moving in the event of a hydraulic hose or line breaking. Load holding valves can either be a check valve or a counterbalance valve. Cylinders can use either a single or double load holding valve. That is to say that one could be use for either holding on retract or extend and in the cases where it is a “double valve” there is a valve for each direction.

Mounts - Mounts are the devices on the cylinder that connect the cylinder to the piece of equipment that the cylinder is mounted to. The most common mounting configurations are listed below;

Trunnion = The trunnion mount is a mounting that is typically housed around the barrel and has two male pins located 180 degrees from one another.

Clevis = A clevis is either located at the rod end or on the end cap or both. The clevis is two narrow tangs that have a machined hole to receive a common pivot pin.

Cross Tube = A cross tube is a tube that is on the end of a rod, mount on the end cap or both. It has a machined hole to receive a pivot pin.

Spherical Bearing = A spherical bearing is a bearing that accommodates some misalignment of one or both pivot pins. It is a bearing that is pressed in to a tang and is located at the rod end, base end or both.

Tang = A tang is a tomb stone shaped flame cut piece of steel that has a precision hole machined in it to receive a pivot pin. A tang is locate don the end of the rod, located on the end cap or both.

Pilot Operated Check Valve - A Pilot Operated Check Valve is a valve that allows free flow in one direction and non in the opposite direction. Flow is allowed on the opposite direction only if adequate pressure is required from the system to move. When the pressure is high enough, it feeds the pilot portion of the valve which allows it to open and move the cylinder. See Load Holding Valve.

Piston - The piston is a cylinder component that has multiple purposes. The piston retains the primary seal from the extend side of the cylinder and the retract side of the cylinder. It and is the component that moves back forth from the hydraulic oil. The piston is the mechanical means of connecting and moving the rod in and out of the cylinder as well as serves as a guide for one end of the piston rod.

Operating Pressure - Operating pressure is referred to the hydraulic pressure that a hydraulic system and its components see during normal operating conditions.

PO Check Valve - See Pilot Operated Check Valve

Ports, Cylinder - Cylinder ports are the means in which the cylinder is able to have fluid lines or conduits connected.

O-Ring Boss (SAE) Port = This is a port that has straight or parallel threads as well as an O-Ring to seal the threads.

Pipe Port = Pipe threads are tapered threads that count on interference between the male and female threads to do the sealing.

4-Bolt Flange Port = This is a port that counts on (4) bolts to hold to two halves together. This type uses an O-Ring to do the sealing.

Code 61= Is a 4-bolt port that is rated for 3,000 PSI operating pressure.

Code 62 = Is a 4-bolt port that is rated for 5,000 PSI operating pressure.

BSP = This is a British Standard Pipe Thread

Pressure Spike - Pressure spike is a an increase in operating pressure for a very short duration sometimes due to induced and external forces or due to hydraulic system. The rise in pressure can be high and cause damage the hydraulic components of the system.

Proximity Switch - A proximity switch is and inductive style limit switch. These switches are solid state and can be installed in cylinders to sense when the cylinder is at the end of stroke for system requirements.

Rod - The rod is also known as the cylinder shaft or ram. It is the round device that moves in and out of the cylinder. The cylinder can be solid or hollow. The rod is usually plated or heat treated to provide better wear and corrosion resistance. The rod also serves and dynamic sealing surface for the rod seal.

Seals -

Positive Seal = A positive seal is a term that refers to a seal that has the capability to seal with no leakage. A usually given to a piston seal.

Static Seal = This is a seal that does not move. It’s not dynamic it’s static.

Dynamic = This is a seal that seals a moving surface like a rod or a barrel.

Cast Iron Ring = This is a style of piston seal that is a non-positive seal. It is made from cast iron and is like the piston rings on and engine piston.

U-Cup = This is a very common seal that is usually made from rubber or urethane. They are commonly used for dynamic sealing for either a piston or rod seal.

Loaded U-Cup = Also called a Poly-Pak, a loaded u-cup has an o-ring installed in the u-cup to help it seal at cold temperatures and low pressures.

Vee-Packing = A vee-packing is an older technology that is still seen today especially with telescopic cylinders. It consists of a number of rubber molded with cotton u-cup type seals stacked on top of one another. This is a sealing configuration that counts on a significant amount of squeeze or interference in order to provide sealing properties.

Side Load - Side load is a term that is reference on how much load off to the side or eccentric load the hydraulic cylinder rod has placed upon it. Normally, cylinder manufacturers do not want any side load place upon the cylinder. Side load will definitely reduce the life of the cylinder. The more the side load to sooner it will wear out or fail. When a known side load condition exists, the factory engineering should become involved to design the cylinder accordingly.

Single Acting Hydraulic Cylinder - A single acting cylinder is a cylinder that has power in one direction, either extend or retract. The means of returning the cylinder is either accomplished with the load or with a spring.

Smart Hydraulic Cylinder - Smart cylinder is a generic term for a cylinder that has the means either internally or externally to provide an electrical output that correlated to the position of the cylinder. Many different types of technologies can be used to make an otherwise conventional cylinder smart.

Telescopic Hydraulic Cylinder - A telescopic cylinder is a cylinder that uses a more that one section to extend. The moving section are called sleeves. Telescopic cylinders can either be single or double acting. Telescopic cylinders are used in applications where the retracted length needs to be shorter than half of the extended length.

|